Control and monitor heating cables

Thermostats and controllers for pipe trace heating

As important components for electrical trace heating, thermostats and controllers assume various key tasks. They are used for regulation and monitoring, and ensure cost-effective, energy-efficient, secure and reliable operation of the pipe trace heating. Our range includes controllers and thermostats for many systems.

Product

Adjustment range

Max. Contact

Sensor type Sensor length

Download Technology

Download Approval

ETS-05-L2-E

ETS-05-L2-E

0 … +199 °C

IP 66

-40 … +60 °C

ETS-05-L2-E

32 A

230 VAC

ETS-05-L2-E

Pt100 PTFE

2,0 m

-55 … +260 °C

ETS-05-H2-E

ETS-05-H2-E

0 … +499 °C

IP 66

-40 … +60 °C

ETS-05-H2-E

32 A

230 VAC

ETS-05-H2-E

Pt100 VA

2,0 m

-55 … +585 °C

ETS-05-A2-E

ETS-05-A2-E

0 … +49 °C

IP 66

-40 … +60 °C

32 A

230 VAC

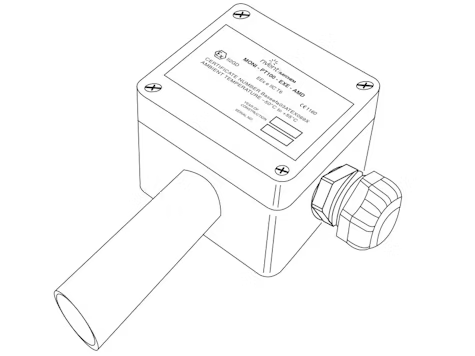

MONI-PT100-EXE-AMB Ex ambient temperature sensor

T-M-20-S/+0+120C/EX

0 … +120 °C (R)

0 … +120 °C (B)

IP 65

-40 … +70 °C

16 A

230 VAC

400 VAC

Capillary tube

2x 2,0 m

-40 … +138 °C (R)

-40 … +138 °C (B)

T-M-20-S/+0+200C/EX

0 … +200 °C (R)

+50 … +300 °C (B)

IP 65

-40 … +70 °C

16 A

230 VAC

400 VAC

Capillary tube

2x 2,0 m

-40 … +230 °C (R)

-40 … +345 °C (B)

T-M-20-S/+50+300C/EX

+50 … +300 °C (R)

+50 … +300 °C (B)

IP 65

-40 … +70 °C

16 A

230 VAC

400 VAC

Capillary tube

2x 2,0 m

-40 … +345 °C (R)

-40 … +345 °C (B)

Product

Adjustment range

Max. Contact

Sensor type Sensor length

Download Technology

Download Approval

AT-TS-13

-5 … +15 °C

IP 65

-20 … +50 °C

230 VAC

16 A

230 VAC

PTC PVC

3,0m

80 °C

AT-TS-14

0 … +120 °C

IP 65

-20 … +50 °C

230 VAC

16 A

230 VAC

PTC silicone

3,0 m

160 °C

RAYSTAT V5

0 … +90 °C

NTC-sensor

0 … +250 °C

Pt100-sensor

(Zubehör)

IP 65

-40 … +40 °C

230 VAC

Last

25 A

230 VAC

Alarm

1-pole change-over contact,

potential-free

ohmic load only

1,0 A @ 30 VDC

(max. 60 VDC)

0,5 A @ max. 125 VAC

NTC

2 kOhm @ 25°C

-40…+90°C

5 x 20 mm

5,0 m cable

2-cores

(Extendable up to max. 150 m, cross-section 1,5mm²

Pt100 Silicone)

Pt100 3-conductors

(accessories)

T-M-10-S/+x+y

0 … +50 °C

0 … +200 °C

+50 … +300 °C

IP 65

-20 … +80 °C

16 A

230 VAC

Capillary tube

2x 2,0 m

-40 … +60/+230/+345 °C (R)

-40 … +170/+230/+500 °C (B)

T-M-20-S/x+y

0 … +50 °C

0 … +200 °C

+50 … +300 °C

IP 65

-20 … +80 °C

16 A

230 VAC

Capillary tube

2x 2,0 m

-40 … +60/+230/+345 °C (R)

-40 … +170/+230/+500 °C (B)

RAYSTAT-CONTROL-11-DIN

0 … +63 °C

IP 20

-10 … +55 °C

230 VAC

16 A

230 VAC

Pt100 silicone

3,0 m

200 °C

Elexant 450c

- with colour touch screen (for housing installation / MPL) for 2 separate heating circuits - replacement type RAYSTAT-CONTROL-11-DIN

0 … +85 °C

NTC-Fühler

0 … +250 °C

Pt100-Fühler

(Zubehör)

IP 20

0 … +40 °C

230 VAC

Last

2* 4 A

230 VAC

Alarm

1-poliger Wechsler, potenzialfrei

nur ohm’sche Last

2,0 A @ max. 250 VAC

1 Stück NTC

2 kOhm @ 25°C

-40…+90°C

5 x 20 mm

5,0 m Leitung

2-adrig

(bis max. 150 m verlängerbar,

Querschnitt 1,5mm2

Pt100 Silikon)

2. Fühler und/oder

Pt100 3-Leiter

(Zubehör)

HWAT-ECO-V5

Maintain the desired water temperature

37 °C…65 °C

20 A

NTC / 3m

HWAT-T55 (duplicate)

Doppel-Thermostat Dachrinne

Bereich I: 0 °C bis +6 °C

Bereich II: –25 °C bis –5 °C

Nachheizzeit 0…3 Stunden

Fühlereinstellung -10 K…+10 K

Betriebsmodi:

EIN: Normal; Thermostat in Betrieb

AUS: Relais offen

Test: 30 min Dauerbetrieb

230 VAC – 16 A Last

230 VAC – 8 A Alarm

NTC im Gehäuse, Anschlussklemmen 2x 1,5 mm²

Elexant 650c-Modbus

mit Farb-Touchscreen (für Gehäuseeinbau / MPL) für Dachrinnen und Freiflächen

- Hinweis

Temperatur- /Feutfühler seperat zu bestellen

Einstellbereiche siehe zugehörige Sensoren

E650C-R Dachrinnen

E650C-G Freiflächen

IP 20

0 … +40 °C

230 VAC

Last

2* 4 A

230 VAC

Alarm

1-poliger Wechsler, potenzialfrei

nur ohm’sche Last

2,0 A @ max. 250 VAC

Siehe zugehörige Sensoren

E650C-R Dachrinnen

E650C-G Freiflächen

E650C-R Sensor

suitable for Elexant 650c-Modbus

- Hinweis

Temperatur- /Feutfühler seperat zu bestellen

-30…+80°C Temperaturbereich

-20…+30°C Arbeitsbereich für Feuchtefühler

Sensorlänge 105 mm mit

Anschlussleitung

4*0,5 mm² 6 m

E650C-G Sensor

suitable for Elexant 650c-Modbus

- Hinweis

Temperatur- /Feutfühler seperat zu bestellen

-30…+75°C Temperaturbereich -20…+30°C Arbeitsbereich für Feuchtefühler

Sensordurchmesser 68 mm mit Anschlussleitung 4*0,5 mm² 20 m

Product

Description

Download Technology

Download Approval

Elexant 5010i

Elektronischer Begleitheizungsregler mit lokaler Regelung und zentraler Überwachung OHNE Sicherheitstemperaturbegrenzer, MIT parametrierbarer Selbstüberwachung (z.B. durch monatliche automatische Einschaltung und Eigenprüfung).

Elexant 5010i LIM

Electronic trace heating controller with local control and central monitoring WITH safety temperature limiter, WITH parameterizable self-monitoring (e.g. through monthly automatic switch-on and self-test).

Product

Sensor Information

Adjustment range

Adjustment range

Download Technology

Download Approval

MONI-PT100-NH

-50 … +180 °C

+400 °C

Pt100

2-wire

-50 … +180 °C

2,0 m / silicone

Polycarbonate

IP 66

-30 … +80 °C

MONI-PT100-EXE

-100 … +500 °C

+500 °C

Pt100

3-wire

-100 … +500 °C

2,0 m / VA

Polycarbonate

IP 66

-50 … +60 °C

MONI-PT100-EXE-SENSOR

-100 … +500 °C

+585 °C

Pt100

3-wire

-100 … +500 °C

2,0 m / VA

Screw connection

-50 … +60 °C

MONI-PT100-EXE-AMB

-100 … +500 °C

+500 °C

Pt100

3-wire

-100 … +500 °C

2,0 m / VA

Polycarbonate

IP 66

-50 … +60 °C

MONI-PT100-4/20MA

-100 … +500 °C

+500 °C

Pt100

3-wire

-100 … +500 °C

2,0 m / VA

Polyester glass fibre reinforced

IP 66

-50 … +60 °C

MONI-PT100-260/2

- Hinweis

Ex nur bei eigensicheren Schaltungen

-50 … +260 °C

+400 °C

Pt100

3-wire

2,0 m / PTFE

Screw connection

-40 … +75 °C

Thermostats and temperature controllers

Efficient control and regulation of pipe trace heating

Heizkabel und Heizbänder mit Thermostat kom

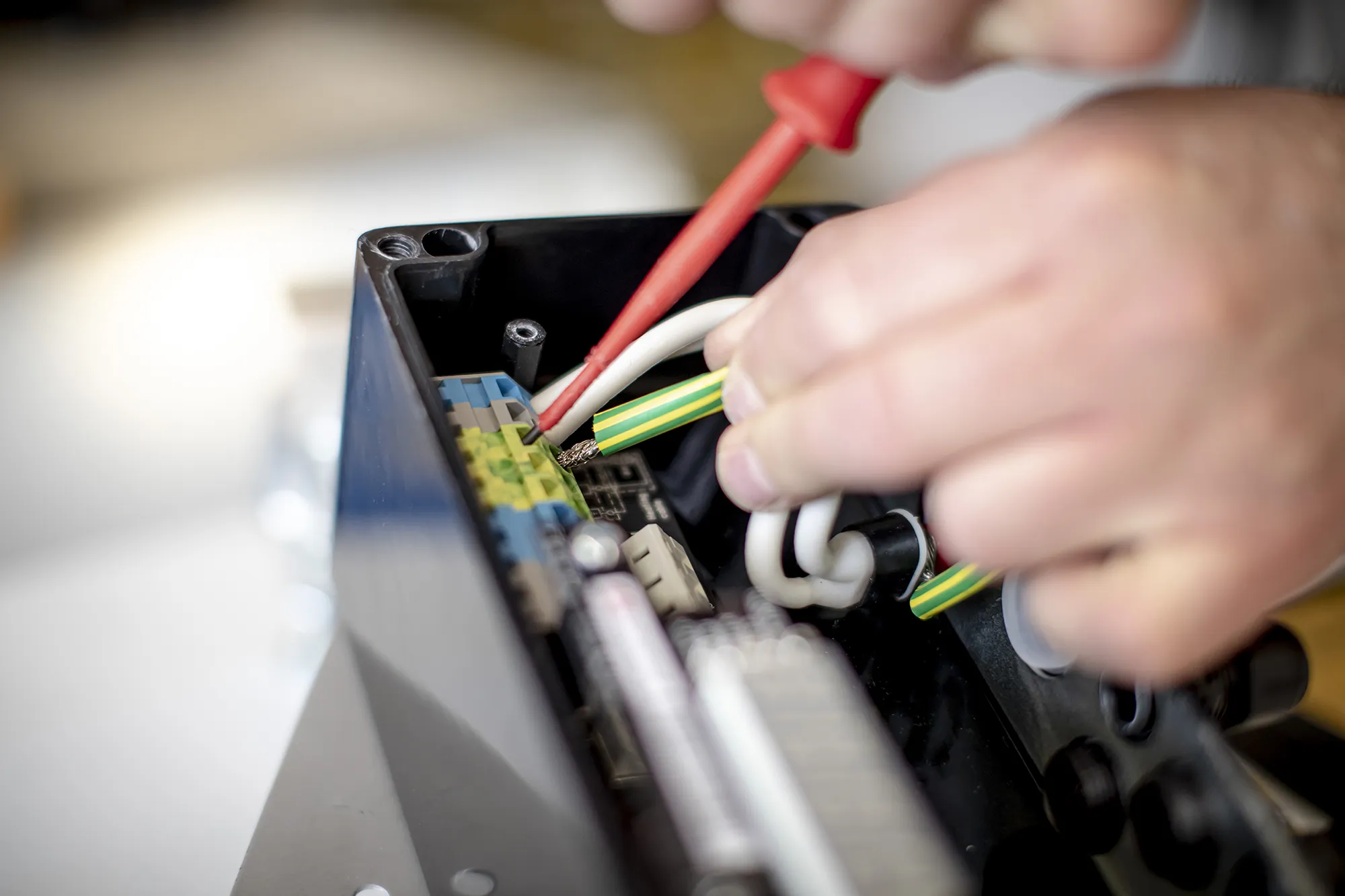

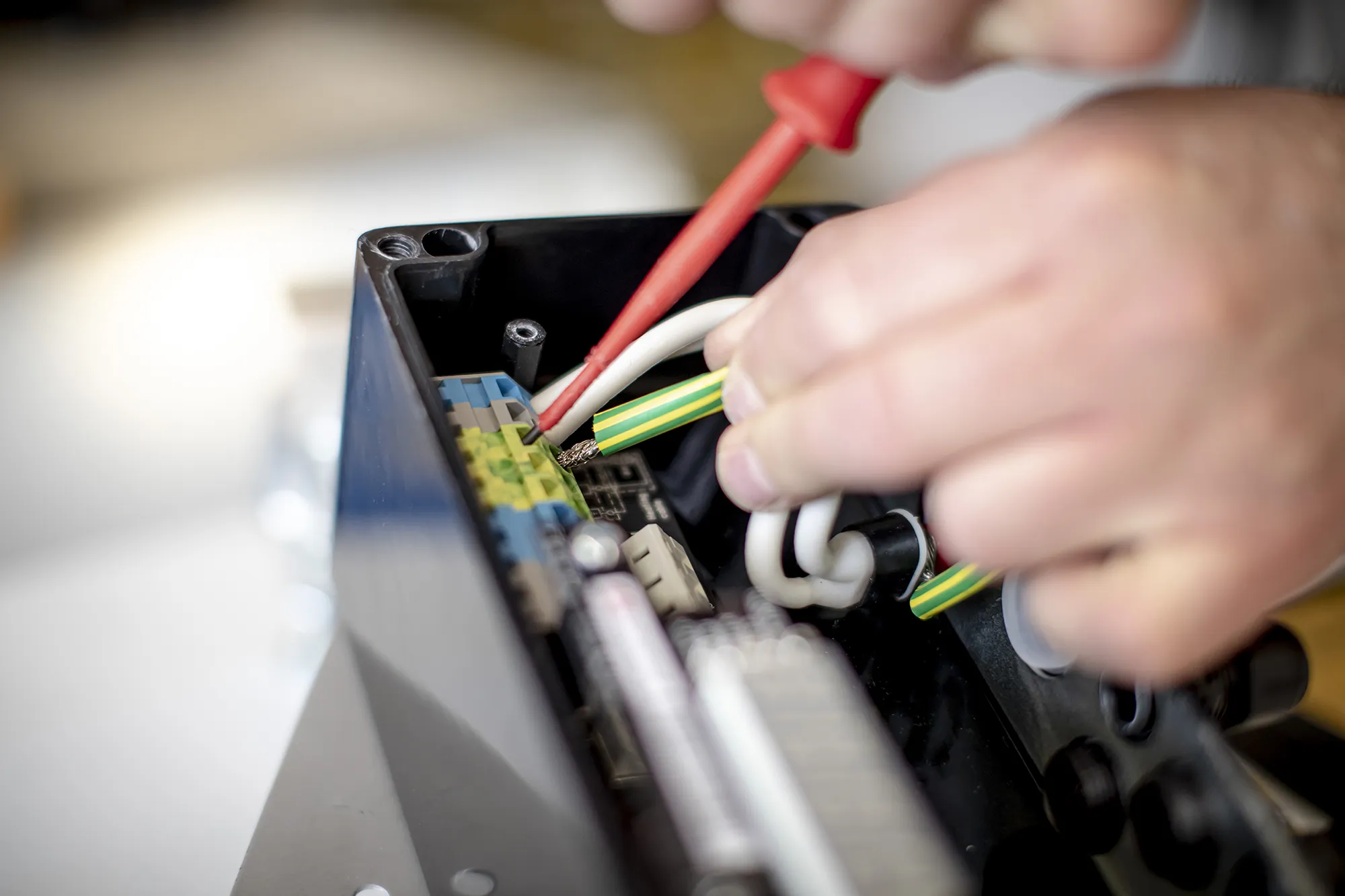

Thermostats and controllers enable precise regulation of pipe trace heating temperatures. Depending on the controller version, some devices can communicate with the control system – via Modbus or Profibus, for example. Depending on the application, controllers and thermostats can switch based on pipe temperature (contact control) or ambient temperature. The controllers can be placed either centrally in the control cabinet or decentrally on site (e.g. on the pipe). The automatic temperature control saves energy and thus costs.

Keep a constant overview of the right temperature for frost protection

Thermostats for monitoring trace heating

In addition to temperature control, thermostats for trace heating with a display and connection to the process control system also monitor the trace heating. Thermostats with a display are particularly easy to use and enable quick access to important information such as the status, any error messages, pipe temperature and ambient temperature, and allow manual adjustments for the optimal configuration, e.g. to maintain frost protection. Depending on the model, the products can have an alarm function that immediately displays a temperature deviation from the target or transmits this to the control system using a fault message contact. Thermostats and controllers are essential elements for efficient and reliable trace heating. You will find the right control technology for any system in our product range.

Would like some product advice?

Get in touch with our team of experts! Everything you get from ZIEGLER ENGINEERING is from a single source – from planning and commissioning through to maintenance of your electrical trace heating.

Prevent frost damage

Use in a wide range of areas

The most common applications for trace heating include frost protection and process temperature maintenance. Just like the heating cables themselves, controllers and thermostats for pipe trace heating must also be tailored to the respective area of application. The ZIEGLER ENGINEERING range includes products for both simple and complex applications as well as for hazardous areas. Safety plays a key role there in particular. The products approved for such applications ensure reliable control and monitoring of the trace heating even under challenging conditions.

High-quality thermostats and controllers for trace heating

Reliable frost protection with ZIEGLER ENGINEERING

When it comes to the design, installation and maintenance of trace heating, ZIEGLER ENGINEERING is your reliable partner with 50 years of experience, extensive storage capacities and an all-round service for pipe trace heating, including the associated control and monitoring. Thanks to our extensive range of thermostats for trace heating, complex control technology and all other components related to pipe trace heating, supplemented by the expertise of our specialists, we also implement your system in a tailored and efficient manner in line with your specifications.

Further product categories

Heating cables

Our versatile range of heating cables ensures the right temperature and reliable frost protection outdoors.

Components and accessories

Optimise trace heating performance with end terminations, connectors, and other accessories.

Innovative special solutions

Custom trace heating solutions from ZIEGLER ENGINEERING for construction and special applications.

We provide support for your project

Get in touch with our team of experts

ZIEGLER ENGINEERING is your partner when it comes to electrical trace heating. We offer a wide range of products, vast experience and sound expert knowledge.